From inside (document excerpt):

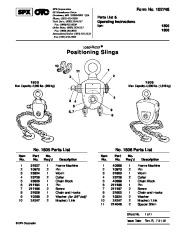

Form No. 102748 Parts List & Operating Instructions for: 1805 1806 Positioning Slings 10 11 2 1805 Max. Capacity=2,000 lbs. (909 kg) Load-Rotor ® 1 2 1806 Max. Capacity=4,000 lbs. (1,818 kg) 4 3 4 5 9 8 6, 7 No. 1805 Parts List Item No. Part No. 31627 10973 23524 23728 23525 211184 211185 31609 10258 24247 No. Req’d Description Frame Machine Pin Worm Collar Chain Block Pin Screw Chain and Hooks Washer (for 3/8 ” bolt) Bracket / Link Item No.

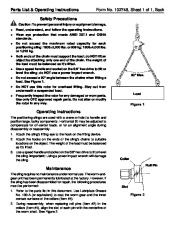

11 No. 1806 Parts List Part No. 40568 10973 31803 23728 40569 Description Frame Machine Pin Worm Collar Chain Block Pin Screw Chain and Hooks Washer Bracket / Link Spacer Shim 1 of 1 Sheet No. SPX Corporation Issue Date: Rev. B, 7-31-02 Parts List & Operating Instructions Safety Precautions Form No. 102748, Sheet 1 of 1, Back Caution: To prevent personal injury or equipment damage, · · Read, understand, and follow the operating instructions. Wear eye protection that meets ANSI Z87.1 and OSHA standards. Do not exceed the maximum rated capacity for each positioning sling: 1805=2,000 lbs. or 909 kg; 1806=4,000 lbs. or 1,818 kg. Both ends of the chain must support the load; do NOT lift an object by attaching only one end of the chain. The weight of the load must be balanced as it’s lifted. Use a speed handle and socket on the 5/8 ” hex drive to tilt or level the sling; do NOT use a power impact wrench. Do not exceed a 90° angle between the chains when lifting a load. See Figure 1. Do NOT use this rotor for overhead lifting. Stay out from underneath a suspended load. Frequently inspect the rotor for any damaged or worn parts. Use only OTC approved repair parts. Do not alter or modify the rotor in any way. Load Figure 1 90° Max. Operating Instructions The positioning slings are used with a crane or hoist to handle and position large, bulky components. Horizontal tilt may be adjusted to compensate for off-center loads, or for an alignment angle during disassembly or reassembly. 1. Attach the sling’s lifting eye to the hook on the lifting device. 2. Attach the hooks on the ends of the sling’s chains to suitable locations on the object. The weight of the load must be balanced as it’s lifted. 3. Use a speed handle and socket on the 5/8 ” hex drive to tilt or level the sling. Important: Using a power impact wrench will damage the sling. Collar Roll Pin Maintenance The sling requires no maintenance under normal use. The worm-andgear unit has been permanently lubricated at the factory. However, if the sling has been disassembled for repair, the following procedures must be performed: 1. Refer to the parts list in this document. Use Lubriplate Grease No. 130-A (or equivalent) to coat the worm gear and the inner contact surfaces of the collars (Item #4). 2. During reassembly, when replacing roll pins (Item #2) in the collars (Item #4), align the slot of each pin with the centerline of the worm shaft. See Figure 2. Slot Figure 2

SPX OTC 1805 1806 Positioning Slings Max Capacity 2000 Lbs 909 Kg Load Rotor Owners Manual - 1 of 2

SPX OTC 1805 1806 Positioning Slings Max Capacity 2000 Lbs 909 Kg Load Rotor Owners Manual - 1 of 2 SPX OTC 1805 1806 Positioning Slings Max Capacity 2000 Lbs 909 Kg Load Rotor Owners Manual - 2 of 2

SPX OTC 1805 1806 Positioning Slings Max Capacity 2000 Lbs 909 Kg Load Rotor Owners Manual - 2 of 2