From inside (document excerpt):

16600 Operating Manual — English Refrigerant Leak Detector 1 Manual de Operación — Spanish Detector de Fugas de Refrigerante 7 Manuel d’utilisation — French Détecteur de fuites de frigorigène 13 Bedienungsanleitung — German Kältemittel-Lecksuchegerät 19 Manuale dell’operatore — Italian Sensore di perdite di refrigerante . 25 Table of Contents Introduction Controls and Indicators . Features . Operation Maintenance .

Heating, Ventilating and Air Conditioning User Manual Free Download. HAVC Operator’s Manual. Auto AC Free Instruction Manual Download PDF.

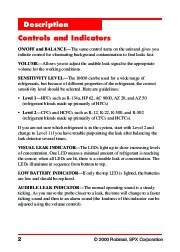

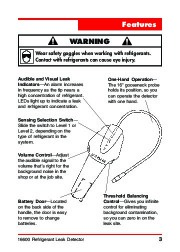

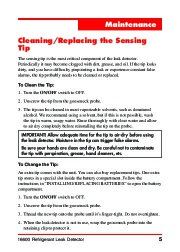

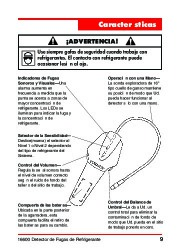

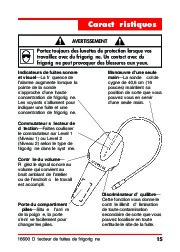

Replacement Parts Specifications . 1 2 3 4 5 6 6 Introduction The 16600 is an electronic leak detector used to detect refrigerant leaks in air conditioning and refrigeration systems. It features a sensitivity selection switch which allows it to be used with CFCs and HCFCs at one setting and HFCs at the other. The unit is able to detect leaks smaller than 1/2 ounce per year. Other features include audible and visual leak indicators, a volume control, a threshold balancing control and a 16 ” gooseneck probe, which holds its position for one-handed operations. When the unit is not being used, the probe wraps into a retaining clip on the back of the case. (2N08) Refrigerant Leak Detection Equipment Design Certified by Underwriters Laboratories, Inc.® to meet SAE J-1627 (1993) for R-12 and R-134a refrigerants. 16600 Refrigerant Leak Detector 1 Description Controls and Indicators ON/OFF and BALANCE–The same control turns on the unit and gives you infinite control for eliminating background contamination to find leaks fast. VOLUME–Allows you to adjust the audible leak signal to the appropriate volume for the working conditions. SENSITIVITY LEVEL–The 16600 can be used for a wide range of refrigerants, but because of different properties of the refrigerant, the correct sensitivity level should be selected. Here are guidelines: · Level 1–HFCs such as R-134a, HP 62, AC 9000, AZ 20, and AZ 50 (refrigerant blends made up primarily of HFCs) · Level 2–CFCs and HCFCs such as R-12, R-22, R-500, and R-502 (refrigerant blends made up primarily of CFCs and HCFCs). If you are not sure which refrigerant is in the system, start with Level 2 and change to Level 1 if you have trouble pinpointing the leak after balancing the leak detector several times. VISUAL LEAK INDICATOR–The LEDs light up to show increasing levels of concentration. One LED means a minimal amount of refrigerant is reaching the sensor; when all LEDs are lit, there is a sizeable leak or concentration. The LEDs illuminate in sequence from bottom to top. LOW BATTERY INDICATOR–If only the top LED is lighted, the batteries are low and should be replaced. AUDIBLE LEAK INDICATOR–The normal operating sound is a steady ticking. As you move the probe closer to a leak, the tone will change to a faster ticking sound and then to an alarm sound (the loudness of this indicator can be adjusted using the volume control). 2 1 2000 Robinair, SPX Corporation Features WARNING Wear safety goggles when working with refrigerants. Contact with refrigerants can cause eye injury. Audible and Visual Leak Indicators–An alarm increases in frequency as the tip nears a high concentration of refrigerant. LEDs light up to indicate a leak and refrigerant concentration. Sensing Selection Switch– Slide the switch to Level 1 or Level 2, depending on the type of refrigerant in the system. Volume Control–Adjust the audible signal to the volume that’s right for the background noise in the shop or at the job site. One-Hand Operation– The 16 ” gooseneck probe holds its position, so you can operate the detector with one hand. Battery Door–Located on the back side of the handle, the door is easy to remove to change batteries. Threshold Balancing Control–Gives you infinite control for eliminating background contamination, so you can zero in on the leak site. 16600 Refrigerant Leak Detector 3 Operation The first time you use the 16600 leak detector, install the batteries before turning on the unit.

Robinair SPX 16600 Refrigerant Leak Detector Owners Manual - Enlarge page 1 of 32

Robinair SPX 16600 Refrigerant Leak Detector Owners Manual - Enlarge page 1 of 32 2 of 32

2 of 32 3 of 32

3 of 32 4 of 32

4 of 32 5 of 32

5 of 32 6 of 32

6 of 32 7 of 32

7 of 32 8 of 32

8 of 32 9 of 32

9 of 32 10 of 32

10 of 32 11 of 32

11 of 32 12 of 32

12 of 32 13 of 32

13 of 32 14 of 32

14 of 32 15 of 32

15 of 32 16 of 32

16 of 32 17 of 32

17 of 32 18 of 32

18 of 32 19 of 32

19 of 32 20 of 32

20 of 32 21 of 32

21 of 32 22 of 32

22 of 32 23 of 32

23 of 32 24 of 32

24 of 32 25 of 32

25 of 32 26 of 32

26 of 32 27 of 32

27 of 32 28 of 32

28 of 32 29 of 32

29 of 32 30 of 32

30 of 32 31 of 32

31 of 32 32 of 32

32 of 32