From inside (document excerpt):

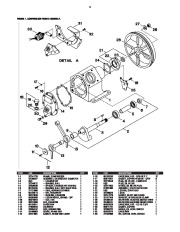

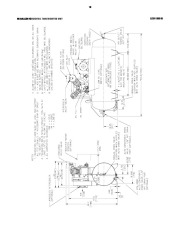

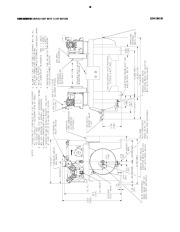

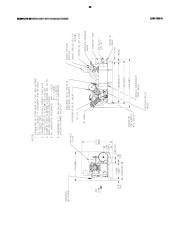

2475 Air Compressor Parts List C.C.N : REV. : DATE : 22400394 A JANUARY 2004 3 FIGURE 1. COMPRESSOR FRAME ASSEMBLY. ITEM 1-1 1-2 1-3 1-4 1-5 1-6 1-7 1-8 1-9 1-27 1-28 1-10 1-11 1-12 1-13 1-14 1-15 CCN 32247728 32496507 NSS 32248122 32006496 95134185 37127669 95433173 30210199 95081808 95076816 30210298 95101911 37605193 32004152 32496663 32247884 DESCRIPTION FRAME, COMPRESSOR ASSEMBLY, CRANKSHAFT COMPLETE · CRANKSHAFT · BEARING, BALL · SPACER, CRANKSHAFT BEARING · BEARING, BALL WITH SNAP RING · RING, BEARING RETAINER · KEY, WOODRUFF · BUSHING, CRANKPIN · LOCKWASHER, SPRING – 3/4 ” · NUT, HEX CAP, CRANKPIN CAPSCREW LOCKWIRE ROD, CONNECTING COVER, FRAME END GASKET, FRAME END COVER QTY 2 1 2 1 1 ITEM 1-16 1-17 1-18 1-19 1-20 1-21 1-22 1-23 1-24 1-25 1-26 1-26 1-29 1-30 1-31 1-32 1-33 CCN 95105250 95674651 32279549 NSS 32247850 97331060 NSS 32499923 32247876 32157349 32496432 32496424 95053526 95674701 32295222 95053070 22102388 DESCRIPTION CAPSCREW, HEX – 5/16-18 X 1 ” GASKET, COPPER WASHER – 5/16 ” PLUG, OIL FILLER – COMPLETE PLUG, OIL FILLER O-RING, OIL FILLER PLUG ASSEMBLY, SHAFT END COVER L COVER, SHAFT END L SEAL GASKET, SHAFT END COVER BRACKET, INTERCOOLER CLAMP BELTWHEEL ELECTRIC MOTOR DRIVE BELTWHEELGASOLINE ENGINE DRIVE CAPSCREW, HEX – 1/2-13 X 3/4 ” GASKET, COPPER BAFFLE, OIL LEVEL SWITCH CAPSCREW KIT, LOW OIL LEVEL SWITCH QTY 12 8 1 2 1 4 FIGURE 2.

Air Compressor User Manual Free Download. Air Compressor Operator’s Manual. Free Instruction Manual Download PDF.

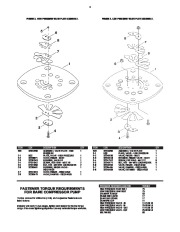

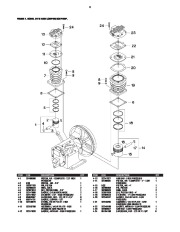

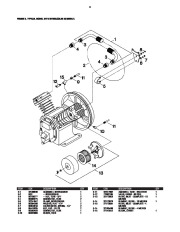

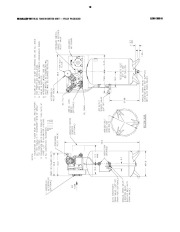

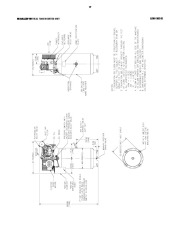

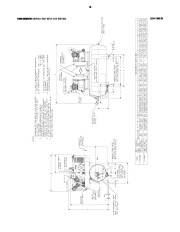

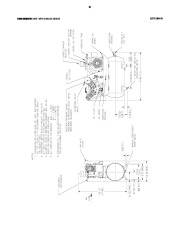

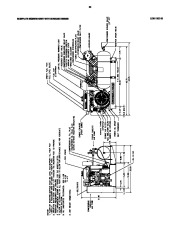

HIGH PRESSURE VALVE PLATE ASSEMBLY. FIGURE 3. LOW PRESSURE VALVE PLATE ASSEMBLY. ITEM REF. 2-1 2-2 2-3 2-4 2-5 2-6 2-7 2-8 CCN 32310799 NSS 32236671 32297343 97511042 97511059 32295461 32241010 32295479 DESCRIPTION ASSEMBLY, VALVE PLATE – HIGH PRESSURE PLATE, VALVE – HIGH PRESSURE VALVE, FINGER – INLET RETAINER, VALVE HP SCREW, HEX HEAD – M3 X 16 NUT, HEX – M3 WITH LOCKWASHER RETAINER, FINGER VALVE DISCHARGE VALVE, FINGER – DISCHARGE VALVE, DAMPER – DISCHARGE QTY 1 2 2 ITEM REF. 3-1 3-2 3-3 3-4 3-5 3-6 3-7 3-8 CCN 32248205 NSS 32248130 32248148 32247512 32248171 32248155 32294464 32248163 DESCRIPTION ASSEMBLY, VALVE PLATE PLATE, VALVE – LOW PRESSURE VALVE, FINGER – INLET RETAINER, FINGER VALVE – INLET SCREW, HEX HEAD – M4 X 12 NUT, HEX – M4 WITH LOCKWASHER VALVE, FINGER – DISCHARGE VALVE, DAMPER – DISCHARGE VALVE, RETAINER – DISCHARGE QTY 1 6 6 FASTENER TORQUE REQUIREMENTS FOR BARE COMPRESSOR PUMP Torque values for critical nut, bolt, and capscrew fasteners are listed below. Gradually and evenly in two stages, tighten each fastener to the final torque using a criss-cross tightening sequence. Use only calibrated torque wrenches. THREADED FASTENER LOCATION HIGH PRESSURE HEAD BOLT LOW PRESSURE HEAD BOLT CYLINDER FLANGE FRAME END COVER SHAFT END COVER CRANKPIN CAP HIGH PRESSURE VALVE – IN LOW PRESSURE VALVE – IN HIGH PRESSURE VALVE – OUT LOW PRESSURE VALVE – OUT BELTWHEEL TORQUE 75 75 50 17 17 11 11-15 IN LB 25-30 IN LB 11-15 IN LB 25-30 IN LB 60 5 FIGURE 4. MODEL 2475 BARE COMPRESSOR PUMP. ITEM 4-1 4-2 4-3 4-4 4-5 4-6 4-7 4-8 4-9 4-10 4-11 4-12 CCN 32496598 NSS 30287783 30298020 32307910 32247868 32247652 95053567 95674701 32246878 32310799 32247926 DESCRIPTION PISTON, AIR – COMPLETE – 2.5 ” HIGH PRESSURE PISTON – AIR – 2.5 ” PIN, PISTON RING, LOCK SET, PISTON RING – 2.5 ” GASKET, CYLINDER/FLANGE CYLINDER – 2.5 ” – HIGH PRESSURE CAPSCREW, HEX – 1/2-13 X 1-1/4 ” GASKET, COPPER – 1/2 ” O-RING, VALVE PLATE – HIGH PRESSURE ASSEMBLY, VALVE PLATE – HIGH PRESSURE (SEE FIGURE 2) GASKET, AIRHEAD – HIGH PRESSURE QTY 2 1 2 1 8 8 ITEM 4-13 4-14 4-15 4-16 4-17 4-18 4-19 4-20 4-21 4-22 4-23 4-24 CCN 32247827 32496564 NSS 30288393 30298020 32307928 32293540 32248197 32248205 32248189 32293557 95104188 DESCRIPTION AIRHEAD – HIGH PRESSURE PISTON, AIR – COMPLETE – 4 ” – LOW PRESSURE PISTON, AIR – 4 ” PIN, PISTON RING, LOCK SET, PISTON RING – 4 ” CYLINDER, – 4 ” LOW PRESSURE GASKET, VALVE PLATE – LOW PRESSURE ASSEMBLY, VALVE PLATE – LOW PRESSURE (SEE FIGURE 3) GASKET, AIRHEAD – LOW PRESSURE AIRHEAD – LOW PRESSURE CAPSCREW, HEX – 1/2-13 X 1-3/4 ” QTY 1 2 8 6 FIGURE 5. TYPICAL MODEL 2475 INTERCOOLER ASSEMBLY. ITEM 5-1 5-2 5-3 5-4 5-5 5-6 5-7 5-8 5-9 5-10 CCN 32499196 NSS 95108577 95083275 32247942 95094298 95648150 95416335 95082483 95031860 DESCRIPTION ASSEMBLY, INTERCOOLER · INTERCOOLER · NUT, TUBE – 3/4 ” CONNECTOR, TUBE CLAMP, INTERCOOLER WASHER, FLAT – 1/4 ” LOCKWASHER, SPRING – 1/4 ” NUT, HEX – 1/4-20 CONNECTOR, TUBE ELBOW, TUBE QTY 1 1 2 2 1 2 2 2 1 1 ITEM 5-11 5-12 5-13 5-14 5-13 5-14 5-15 CCN 32247892 72062185 32170953 32170979 37170834 32165466 37143542 DESCRIPTION ASSEMBLY, TUBE – BREATHER VALVE, RELIEF – 80 PSIG FILTER, INLET – COMPLETE – 10 MICRON ELEMENT, FILTER – 10 MICRON FILTER, INLET – COMPLETE – 4 MICRON ELEMENT, FILTER – 4 MICRON ELBOW, STREET QTY 1 1 7 SIMPLEX ELECTRIC MOTOR MODELS AIR COMPRESSOR PUMP CCN DESCRIPTION AIR COMPRESSOR PUMP GROUP 32304370 PUMP, BARE COMPRESSOR 95114476 CAPSCREW, HEX – 1/2-13 X 1-1/2 (TO MOUNT PUMP TO BASE) 95458808 NIPPLE, CLOSE 3/4 X 1-3/8 95716890 LOCKWASHER, SPRING – 1/2 (FOR PUMP MOUNTING CAPSCREWS) CONTROLS CCN 31385693 32174286 32499816 32179038 56288772 32333072 32499626 85582229 32145088 95031795 95426714 56288764 32221228 32322281 32322299 32323172 32323396 32323404 32323412 32333098 32333106 32333114 32334849 32334872 32334880 32209157 95082467 DESCRIPTION COMMON VALVE, SAFETY / RELIEF – 200 PSIG VALVE, SAFETY / RELIEF (DISCHARGE) – 325 PSIG GAUGE, AIR PRESSURE – 0-300 PSIG, 1/4 NPT, 9 O’CLOCK PLUG, PIPE – 1/4 CENTER DISCHARGE UNITS SWITCH, PRESSURE – SIEMENS W / UNLOADER VALVE & LEVER ASSEMBLY, TUBE – PRESSURE SWITCH TO CHECK VALVE ASSEMBLY, DISCHARGE TUBE VALVE, CHECK – 5/8 T X 3/4 NPT ELBOW, TUBE – 3/4 X 3/4 WITH PORT TUBE ELBOW – 5/8 X 1/2 NIPPLE, CLOSE – 1/4 X 7/8 FULLY PACKAGED UNITS SWITCH, PRESSURE – SIEMENS W / UNLOADER VALVE (FULLY PACKAGED UNITS) TEE, MALE BRANCH -1/4 ASSEMBLY, TUBE – PRESSURE SWITCH TO CHECK VALVE 2475N NEMA 1 IFCV ASSEMBLY, TUBE – PRESSURE SWITCH TO CHECK VALVE 2475D NEMA 1 IFCV ASSEMBLY, TUBE – UNL 2475N7.5 PRESS SW TO CK VLV W/ROT SWITC ASSEMBLY, TUBE – MM/CK VLV/ACA C 2475N (INV CK VLV) ASSEMBLY, TUBE – N4 PS/CK VLV 2475D (INV CK VLV) ASSEMBLY, TUBE – MM/CK VLV/TEB G 2475N ASSEMBLY, TUBE – PRESSURE SWITCH TO CHECK VALVE 2475N (SIEMENS) ASSEMBLY, TUBE – PRESSURE SWITCH TO CHECK VALVE 2475D (SIEMENS) ASSEMBLY, TUBE – PRESSURE SWITCH TO CHECK VALVE 2475N7.5 (SIEMENS) ASSEMBLY, TUBE – PRESSURE SWITCH TO CHECK VALVE 2475N5 ASSEMBLY, TUBE – PRESSURE SWITCH TO CHECK VALVE 2475N7.5 ASSEMBLY, TUBE – PRESSURE SWITCH TO CHECK VALVE 2475D5 NIPPLE, LONG – 1/4 X 5 CONNECTOR, MALE – 1/4 X 1/4 QTY 1 1 4 1 4 BASEPLATE CCN 32195224 32333445 32048993 STARTERS CCN 56272305 56272040 56272057 56272222 56272230 56272164 56272297 56272198 56272131 56272149 56272214 97330229 56272305 56272040 56272057 81292468 56272222 56272164 81292450 56272297 56272198 56277214 DESCRIPTION BASEPLATE PACKAGE GROUP ASSEMBLY, SUBBASE ASSEMBLY, PRESSURE SWITCH TUBE CLAMP DESCRIPTION CENTER DISCHARGE UNITS STARTER, 5HP – 200-1-60 STARTER, 5HP – 230-1-60 STARTER, 5HP – 200-3-60 STARTER, 5HP – 230-3-60 STARTER, 5HP – 460-3-60 STARTER, 5HP – 575-3-60 STARTER, 7.5HP – 230-1-60 STARTER, 7.5HP – 200-3-60 STARTER, 7.5HP – 230-3-60 STARTER, 7.5HP – 460-3-60 STARTER, 7.5HP – 575-3-60 PLATE, STARTER MOUNT FULLY PACKAGED UNITS STARTER, 5HP – 200-1-60 STARTER, 5HP – 230-1-60 STARTER, 5HP – 200-3-60 STARTER, 5HP – 230/460-3-60 STARTER, 5HP – 230-3-60 STARTER, 5HP – 575-3-60 STARTER, 7.5HP – 230/460-3-60 STARTER, 7.5HP – 230-1-60 STARTER, 7.5HP – 200-3-60 STARTER, 7.5HP – 575-3-60 QTY 1 1 2 2 QTY 1 QTY QTY 1 1 4 VAR QTY 1 QTY 1 ELECTRIC DRAIN CCN DESCRIPTION COMMON 54393335 ELBOW, STREET – 1/2 54579248 DRAIN, EDV ELECTRIC 95989638 CONNECTOR, SWIVEL – FEMALE VERTICAL TANK UNITS 32237851 NIPPLE, LONG – 1/2 X 4-1/2 54386974 COUPLING, BRASS – 1/2 95242517 NIPPLE, LONG – 1/2 X 6 DRIVE CCN 32288631 97331656 97331649 97331664 32065526 97331656 32309437 97331680 97331672 95099479 95099511 95099461 32065526 32288631 32036790 32036857 32036865 32281768 54507975 54507967 32175556 54370523 DESCRIPTION MOTORS – CENTER DISCHARGE UNITS MOTOR, 5HP – 230-1-60 MOTOR, 5HP – 230/460-3-60 MOTOR, 5HP – 200-3-60 MOTOR, 5HP – 575-3-60 MOTOR, 5HP – 200-1-60 MOTOR, 5HP – 230-3-60 MOTOR, 7.5HP – 230-1-60 MOTOR, 7.5HP – 230/460-3-60 MOTOR, 7.5HP – 200-3-60 BELTS BELT, V – A62 (5HP CENTER DISCHARGE UNITS) BELT, V – A70 (5HP FULLY PACKAGED UNITS) BELT, V – A60 (7.5HP CENTER DISCHARGE UNITS) MOTORS – FULLY PACKAGED UNITS MOTOR, 5HP – 200-1-60 MOTOR, 5HP – 230-1-60 MOTOR, 5HP – 200-3-60 MOTOR, 5HP – 230/460-3-60 MOTOR, 5HP – 575-3-60 SHEAVE SETS SET, SHEAVE (5HP) SET, SHEAVE (7.5HP, 230-1-60) SET, SHEAVE (7.5HP, ALL EXCEPT 230-1-60) COMMON CAPSCREW, SERRATED WASHER HEAD – 3/8-16 X 1 (MOTOR MOUNTING) NUT, CONICAL KEPS – 3/8 (MOTOR MOUNTING) AIR RECEIVER TANK CCN DESCRIPTION 97336259 TANK, AIR RECEIVER – 80 GALLON VERTICAL (CENTER DISCHARGE UNITS) 32496499 …..

SELECT – CASE OF 12 QUARTS ACCESSORIES INSTALLATION KITS Each Installation Kit combines vibration pads and flexible hose into one kit. The kit consists of (4) 5 X 5 vibration pads and (1) ¾ X 13 flexible hose. CCN DESCRIPTION 38002242 KIT, INSTALLATION SILENCERS Silencers provide excellent noise reduction (2 DBA or 35% reduction in operating noise level) with no pressure drop. CCN DESCRIPTION 32323552 SILENCER VIBRATION PADS Vibration pads are designed to absorb 40-60% of the sound and vibration of your compressor. CCN DESCRIPTION 32320681 PAD, VIBRATION — 4 X 4 STEEL PLATE 32320699 PAD, VIBRATION — 5 X 5 STEEL PLATE 32321002 PAD, VIBRATION — 4 X 4 CORK 32321028 PAD, VIBRATION — 5 X 5 CORK 32321010 PAD, VIBRATION — 6 X 6 CORK FLEX HOSES Flex Hoses give flexibility to compressed air piping systems. They provide thermal growth absorption, misalignment compensation, vibration isolation, reduced stress forces on compressor housings and noise reduction. CCN DESCRIPTION 32323586 HOSE, FLEX — ½ X 11 38335295 HOSE, FLEX — ½ X 36 38338778 HOSE, FLEX — ½ X 72 32323594 HOSE, FLEX — ¾ X 13 38323309 HOSE, FLEX — ¾ X 24 38335303 HOSE, FLEX — ¾ X 36 38338638 HOSE, FLEX — ¾ X 72 32323602 HOSE, FLEX — 1 X 14 38334033 HOSE, FLEX — 1 X 24 38335311 HOSE, FLEX — 1 X 36 38338646 HOSE, FLEX — 1 X 72 32323610 HOSE, FLEX — 1-½ X 18 38323317 HOSE, FLEX — 1-½ X 20-½ 38323325 HOSE, FLEX — 1-½ X 24 Y-STRAINERS Y-Strainers are designed to prevent foreign particles and sludge from moving downstream. CCN DESCRIPTION 32323628 Y-STRAINER, 1/4 32323636 Y-STRAINER, 1/2 INTERCOOLER SEPARATOR KITS Intercooler Separator Kits remove condensate between the first and second stages. CCN DESCRIPTION 32337826 KIT, INTERCOOLER SEPARATOR GASOLINE ENGINE PARTS CCN DESCRIPTION 32305674 FILTER, OIL 32305682 FILTER, AIR 32305690 PRE FILTER 38487039 KIT, MUFFLER 32498545 FILTER, OIL 32498537 FILTER, AIR 32498529 PRE FILTER MODELS KOHLER ENGINE MODELS KOHLER ENGINE MODELS KOHLER ENGINE MODELS KOHLER ENGINE MODELS KAWASAKI KAWASAKI KAWASAKI 12 EXTERNAL CRANKCASE HEATER KITS External crankcase heaters are recommended when ambient temperatures are consitently below 32°F (0°C). An easy-to-install external creankcase heater kit is intended for aftermarket use. Two kits may be required for some applications. CCN DESCRIPTION 97330385 KIT, EXTERNAL CRANKCASE HEATER CONSTANT SPEED CONVERSION KITS Extend the life of your compressor in hot and humid operating conditions by installing Constant Speed Control. CCN DESCRIPTION MODELS 81294621 KIT, CONSTANT SPEED 2475N5/7.5 W/4-FOOT CONVERSION RECEIVER 81294639 KIT, CONSTANT SPEED 2475N7.5 W/3-FOOT CONVERSION RECEIVER 81294688 KIT, CONSTANT SPEED 2475D5 CONVERSION 81295867 KIT, CONSTANT SPEED 2475N5 W/3-FOOT CONVERSION RECEIVER BATTERY SUPPORT KITS The Battery Support Kit will allow a battery to be conveniently mounted on the Kohler, Honda and kawasaki engine driven compressors. The kit contains the battery support, battery hold-down frame and attachment hardware. CCN DESCRIPTION MODELS 32095663 KIT, BATTERY SUPPORT KOHLER, HONDA, KAWASAKI ENGINE MODELS VINYL COVERS Flame retardant vinyl covers are designed to protect gasoline engine compressors from the elements. CCN DESCRIPTION MODELS 97339337 COVER, VINYL KOHLER, HONDA, KAWASAKI ENGINE MODELS 13 GENERAL ARRANGEMENT DRAWINGS BARE COMPRESSOR PUMP G2111000-04 14 BASEPLATE MOUNTED UNIT WITH ELECTRIC MOTOR G2211000-05 15 80-GALLON HORIZONTAL TANK MOUNTED UNIT G2311000-05 16 80-GALLON VERTICAL TANK MOUNTED UNIT — FULLY PACKAGED G2811300-01 17 80-GALLON VERTICAL TANK MOUNTED UNIT G2811302-02 18 TANK MOUNTED DUPLEX UNIT WITH 5 HP MOTORS G2411300-03 19 TANK MOUNTED DUPLEX UNIT WITH 7.5 HP MOTORS G2411301-02 20 BASEPLATE MOUNTED UNIT WITH KAWASAKI ENGINE G2611003-01 21 TANK MOUNTED UNIT WITH KOHLER ENGINE G2711004-01 22 BASEPLATE MOUNTED UNIT WITH KAWASAKI ENGINE G2611002-00 23 TANK MOUNTED UNIT WITH KAWASAKI ENGINE G2711003-01 24 BASEPLATE MOUNTED UNIT WITH HONDA ENGINE G2611000-01 25 TANK MOUNTED UNIT WITH HONDA ENGINE G2711000-02 LOOK WHAT INGERSOLL-RAND CAN DO FOR YOU! Efficient Field Service We maintain a highly trained staff of technicians to service your equipment for preventive maintenance, or to assist you should emergencies ever occur. Complete Repair Service Our trained technicians will repair or overhaul your equipment to factory specifications, using only genuine I-R parts. Special Engineering Service We can help you identify and solve your problems by evaluating your needs and recommending the proper equipment to give you maximum efficiency. Spare Parts By stocking genuine I-R spare parts, we can help you avoid costly delays or substituting inferior parts. Using genuine I-R parts on you I-R equipment will help to keep even older equipment running in good-as-new condition. Complete Stock of Equipment We carry a complete line of I-R equipment and accessories designed to meet any compressed air application. We are backed by I-R’s prompt factory shipment to ensure you on-time delivery. A SUBSTITUTE IS NOT A REPLACEMENT! Ensure you get peak performance and longevity out of your Ingersoll-Rand product by insisting on genuine Ingersoll-Rand replacement parts and maintenance kits. Not only are the replacement parts made to precise dimensions and OEM-specified metallurgy, but each part is backed by the Ingersoll-Rand warranty. Your local Air Center, Distributor, or direct Ingersoll-Rand salesperson will work with you to ensure you get the parts you need to do the job right. Equip your machines with only the best — Ingersoll-Rand genuine parts. NOTE: THE USE OF REPAIR PARTS OTHER THAN THOSE INCLUDED WITHIN THE INGERSOLL-RAND COMPANY APPROVED PARTS LIST MAY CREATE UNSAFE CONDITIONS OR MECHANICAL FAILURES OVER WHICH INGERSOLL-RAND COMPANY HAS NO CONTROL. INGERSOLL-RAND COMPANY SHALL BEAR NO RESPONSIBILITY FOR EQUIPMENT ON WHICH NON-APPROVED REPAIR PARTS ARE INSTALLED. …

Wikipedia’s page for Ingersoll-Rand

Publisher: company.ingersollrand.com

Ingersoll Rand 2475 Air Compressor Parts List - Enlarge page 1 of 28

Ingersoll Rand 2475 Air Compressor Parts List - Enlarge page 1 of 28 2 of 28

2 of 28 3 of 28

3 of 28 4 of 28

4 of 28 5 of 28

5 of 28 6 of 28

6 of 28 7 of 28

7 of 28 8 of 28

8 of 28 9 of 28

9 of 28 10 of 28

10 of 28 11 of 28

11 of 28 12 of 28

12 of 28 13 of 28

13 of 28 14 of 28

14 of 28 15 of 28

15 of 28 16 of 28

16 of 28 17 of 28

17 of 28 18 of 28

18 of 28 19 of 28

19 of 28 20 of 28

20 of 28 21 of 28

21 of 28 22 of 28

22 of 28 23 of 28

23 of 28 24 of 28

24 of 28 25 of 28

25 of 28 26 of 28

26 of 28 27 of 28

27 of 28 28 of 28

28 of 28